VRL AUTOMATION ENGINEERING AND PROJECTS PVT LTD

REFINARY

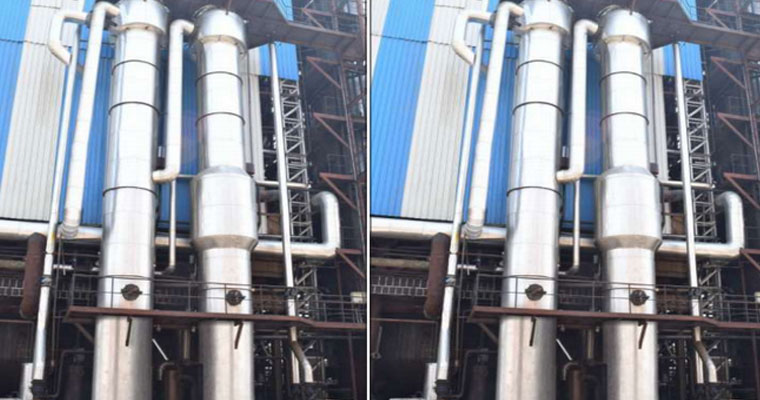

Two Stage Decolourization By Ion Exchange Columns

The Ion Exchange Resin process consisting of two stage decolourization process in series with total 6 columns. Each stage having 3 columns (2 working + 1 stand by). The plant is designed in such a way that any two I E R columns in each stage will be in operation while the third column is under regeneration. The Ion Exchange process is designed to remove anionically charged colorants from clarified & filtered melt liquor. The plant design can be customized to suit specific requirements. The VRL design has proven track record of achieving color of 150 ICUMSA for fine liquor from 550 ICUMSA inlet filtered melt. The ion exchange plant consisting of IER columns, laterals,resin traps,resin transfer system, regeneration system, brine preparation system with various pipelines for melt liquor, brine solution, HCl, compressed air, hot water etc., are totally designed & manufactured by VRL. The IER system of VRL make is working at full rated capacity of 1100 TPD, meeting all design parameters right from day one of commissioning.